After production of all 100 parts needed to make 50 yo-yos were made, we had a couple of assembly parties, which consisted of a couple of steps.

Circuit Assembly

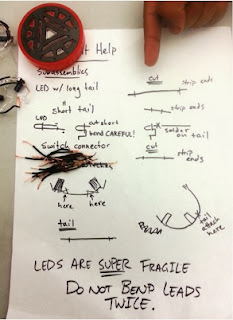

Circuit Construction:

|

| Morgan's wire cutting and stripping instructions |

|

The soldering task was split into two sub-assembly pieces

so the entire circuit assembly process would be much faster.

|

Once circuit assemblies were finished, they would be passed down to be placed into the thermoformed circuit piece with the batteries. From there, the circuit would be tested to make sure all three LEDs worked and if it passed the test in the sample, the piece would be taped up (this is so it would not come in contact with the shim, which would cause the circuit to short).

Circuit Testing Station:

Yo-yo Assembly

Half yo-yo assembly

After the circuit assemblies were done, they would assembled into a body with the thermoformed window and ring.

Testing

Once the yo-yos were made, their string gaps had to measured and they were then put into another pile for testing. This last testing station was to make sure both circuits lit up and to make sure it yo-yoed well.

It turned out assembling the circuits took the longest, with the wire cutting and stripping taking the longest. It took us a while, but we were finally able to finish all 50 yoyos!!

No comments:

Post a Comment